What is a Flatbed Load and How to Optimize Your Transport Efficiency

In the realm of freight transportation, "flatbed loads" play a pivotal role in moving oversized and irregularly shaped cargo efficiently. According to a recent industry report from the American Trucking Associations, flatbed trucking accounts for approximately 10% of all freight transported in the United States, underscoring its significance in the logistics sector. With construction, manufacturing, and agriculture relying heavily on flatbed services, optimizing transport efficiency has never been more critical.

Dr. Emily Carter, a transportation logistics expert, states, "Effective management of flatbed loads can significantly reduce costs and enhance service delivery in an already competitive market." This insight reflects the pressing need for shippers and carriers to adopt innovative strategies, leverage technology, and enhance their operational protocols. As demand for flatbed transportation continues to grow, understanding the intricacies of load optimization will not only streamline operations but also contribute to sustainability goals within the industry.

By examining best practices and emerging trends, stakeholders in the logistics and freight sectors can better navigate the challenges associated with flatbed loads, leading to improved efficiency and profitability in an ever-evolving market landscape.

Understanding Flatbed Loads: Definition and Characteristics

Flatbed loads are a unique category of freight that requires specialized transport due to their size, shape, or weight. Unlike enclosed trucks, flatbed trucks feature an open platform, allowing for the transport of oversized or irregularly shaped cargo that may not fit within the confines of a standard trailer. The flexibility of flatbed loads makes them ideal for shipping construction materials, heavy machinery, and steel beams, which are integral to various industries. According to the American Transportation Research Institute, flatbed trucking represents about 16% of the freight market in the U.S., indicating a significant demand and utilization of this transport method.

Optimizing the efficiency of flatbed transport involves various strategies, from proper loading techniques to route planning. Ensuring that loads are evenly distributed can prevent shifting during transit, which minimizes the risk of damage and enhances safety. A study by the Freight Transportation Research Institute suggests that optimizing load configurations can improve fuel efficiency by up to 15%, which has substantial implications for overall operational costs. Additionally, employing technology such as GPS tracking and route optimization software allows carriers to identify the most efficient pathways, reducing transit times and increasing reliability in flatbed shipping operations. By understanding the unique characteristics of flatbed loads and implementing best practices, transport efficiency can be significantly enhanced.

Types of Cargo Suitable for Flatbed Transport

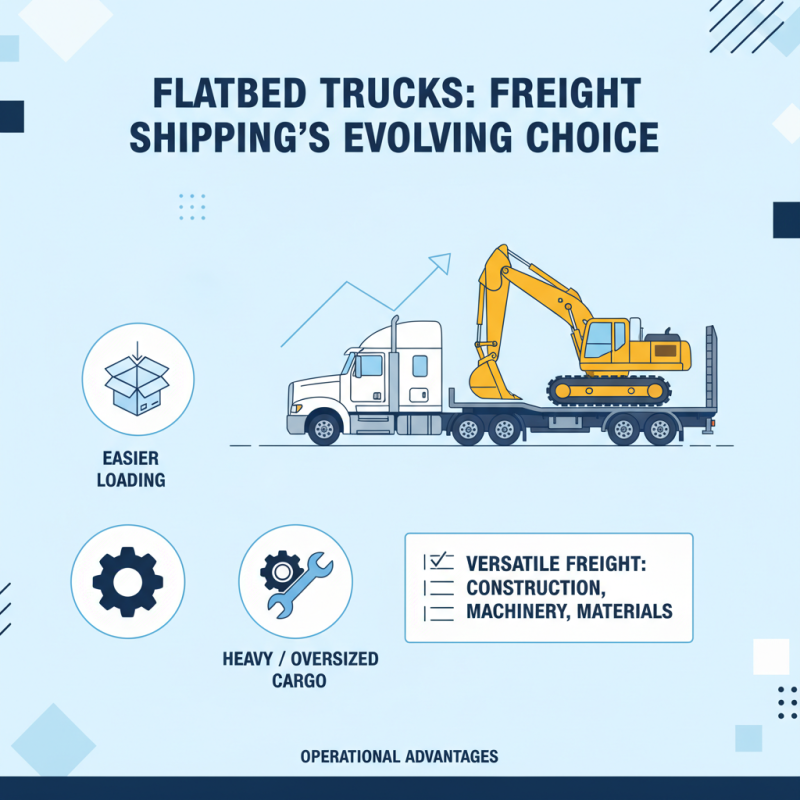

Flatbed transport is a versatile option for moving a wide variety of cargo. This method is particularly suitable for oversized or heavy equipment that cannot be easily loaded onto a standard enclosed trailer. Common types of cargo ideal for flatbed transport include machinery, construction materials, and large metal components. The open design of a flatbed allows for easier loading and unloading from all sides, making it a preferred choice for freight that requires cranes or forklifts.

When using flatbed transport, it's essential to optimize your load for efficiency and safety. **Tip:** Use appropriate securing equipment such as straps, chains, and tarps to ensure that your cargo remains stable throughout the journey. Properly distributing the weight across the flatbed will also help maintain balance and prevent shifting during transit.

Another type of cargo well-suited for flatbed transport includes vehicles and trailers. Transporting cars or construction vehicles is streamlined with flatbeds, as they can accommodate various shapes and sizes. **Tip:** Always measure your cargo dimensions in advance to select the appropriate flatbed size and to avoid any logistical issues. By being mindful of these considerations, you can enhance your transport efficiency while minimizing potential delays.

Benefits of Using Flatbed Trucks for Freight Shipping

Flatbed trucks are an increasingly preferred choice for freight shipping due to their unique design and operational advantages. Unlike traditional enclosed trailers, flatbed trucks provide an open platform that allows for easier loading and unloading of various types of cargo. This accessibility is particularly beneficial for large or heavy items that cannot be easily maneuvered into a closed space. The flatbed's versatile layout accommodates a wide range of freight, from construction equipment to oversized machinery, making it an essential asset in industries that demand flexibility in transportation.

Another significant benefit of using flatbed trucks is their ability to optimize transport efficiency. The open nature of flatbeds not only facilitates quick loading and unloading but also enables the transport of larger loads in a single trip. This reduces the number of trips required and can lead to lower overall shipping costs. Additionally, flatbed trucks are often equipped with various securing mechanisms, ensuring that loads are safely transported while minimizing the risk of damage during transit. Overall, the use of flatbed trucks in freight shipping enhances operational efficiency and supports a streamlined logistics process, making them a preferred choice for many businesses.

Strategies for Optimizing Transport Efficiency with Flatbeds

Optimizing transport efficiency with flatbed loads requires a strategic approach that maximizes space and minimizes time. One effective strategy is to conduct thorough planning before loading. This includes calculating the dimensions and weight of the cargo to ensure it fits securely on the flatbed. Utilizing proper loading techniques, such as distributing weight evenly and securing the cargo adequately, helps prevent shifting during transit, which can lead to damage and delays.

Another key aspect is route optimization. Utilizing technology to analyze traffic patterns, road conditions, and delivery schedules can significantly reduce transit times. By selecting optimal routes that consider these factors, transporters can enhance efficiency and lower fuel costs. Additionally, planning for rest stops and maintaining compliance with local regulations ensures that trips are not only quicker but also safer, reducing the risk of unexpected delays.

Coordinating communication among all parties involved in the transportation process further streamlines operations. Establishing clear channels for updates on shipping status and any potential issues can help in quickly adapting to changes. Whether it's through real-time tracking systems or regular check-ins, effective communication helps keep everyone aligned, allowing for timely responses and adjustments, which is crucial for maintaining high transport efficiency with flatbed loads.

Transport Efficiency of Flatbed Loads: Key Metrics

This chart illustrates key metrics that impact the transport efficiency of flatbed loads, including distance traveled (in miles), load weight (in pounds), transport time (in hours), and fuel efficiency (in MPG). Optimizing these factors can enhance overall transport performance.

Key Considerations for Load Securing and Safety in Flatbed Shipping

Securing loads on flatbed trailers is crucial for ensuring the safety of transported goods and compliance with industry regulations. According to the Federal Motor Carrier Safety Administration (FMCSA), improperly secured loads are a leading cause of accidents on the road, accounting for approximately 30% of cargo-related incidents. To mitigate these risks, it is essential to adhere to best practices for load securing. This includes using appropriate tie-down methods such as straps, chains, or tarps, which should be selected based on the weight and type of the cargo being transported.

Moreover, proper weight distribution is a key consideration in maintaining transport efficiency and safety. The cargo should be evenly distributed across the flatbed to prevent shifting during transit, which can lead to imbalance and potential hazards. The North American Cargo Securement Standards prescribe specific guidelines that classify cargo into different categories, each with its own securing requirements. For example, heavy machinery needs to be secured with a minimum number of tie-downs that correspond to its weight, typically requiring a greater quantity than lighter loads, thereby ensuring stability and adherence to safety regulations. Implementing these considerations not only enhances the overall safety of flatbed shipping but also contributes to operational efficiency by reducing the chances of costly delays and accidents.